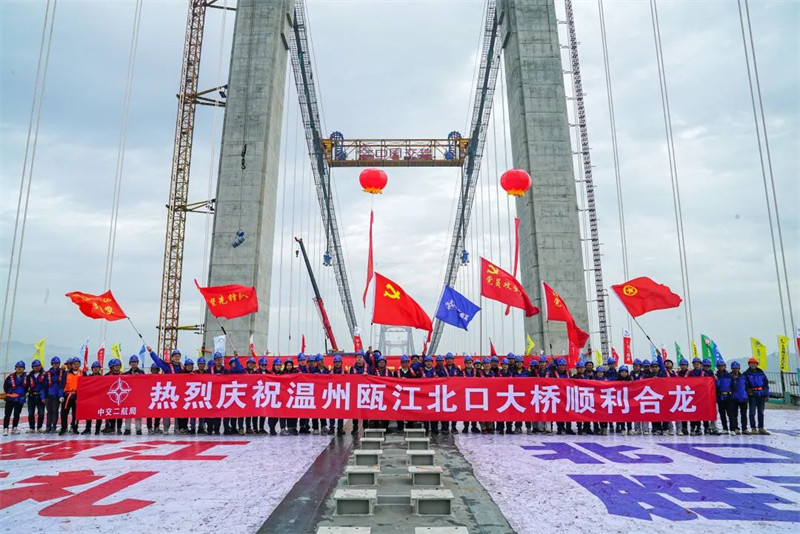

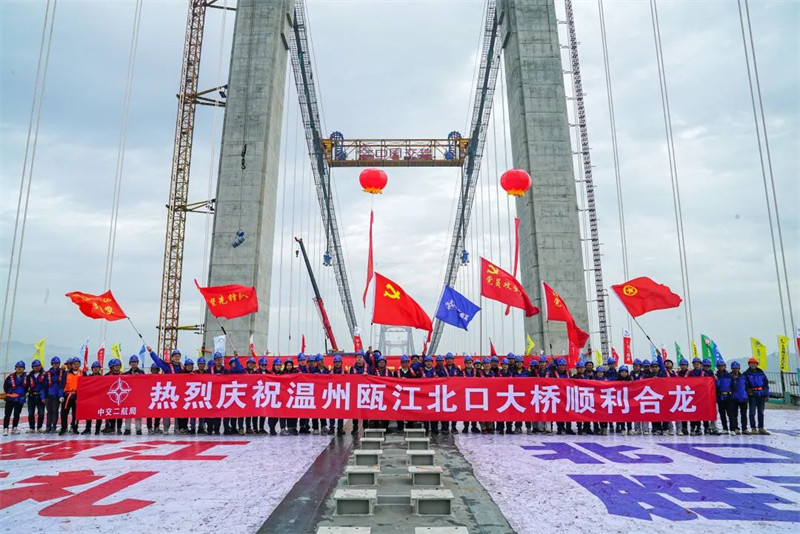

The world's first three-tower, four-span, double-deck steel truss girder suspension bridge opened to traffic

On May 27th, it was built by CCCC Second Aviation Bureau.

The world's first three-tower four-span double-deck steel truss suspension bridge

Wenzhou Oujiang Beikou Bridge completed and opened to traffic

Marking my country's coastal traffic artery

Ningbo to Dongguan National Expressway

The last node realizes the connection

The Beikou Bridge project has a total length of 7913 meters

Among them, the main bridge spanning the Ou River is 2090 meters long

Adopt the design of "two bridges combined"

The upper level is Yong-Dong Expressway

Two-way 6-lane expressway standard

Design speed 100 kilometers per hour

The lower level is the National Highway G228 Nanjin Highway

Two-way 6-lane first-class highway standard

Design speed of 80 kilometers per hour

bridge available

Capacity of 107,000 vehicles per day

Contracted by CCCC Second Aviation Bureau

There are two tenders for civil construction three tenders and four tenders

in

The three civil works started on April 28, 2017

Main construction content

Including South Tower, South Anchorage, South Approach Bridge, etc.

Construction of the Fourth Civil Construction Project started on August 25, 2020

Construction content

Including the main cables and slings of the upper structure of the main bridge

Cable saddle installation and erection, steel truss beam hoisting

and ancillary facilities

Since the construction of the bridge

The project team of CCCC Second Aviation Bureau adheres to the combination of production and research

Forming a three-tower four-span suspension bridge in a strong typhoon area

Superstructure construction and control complete technology

Achievements of a complete set of construction technology for caisson in the land area of the strong tide estuary

Overcome the problems of tight schedule and high security risks

Provides experience and reference for subsequent bridge construction of the same type

The opening of the bridge will help Wenzhou make good use of the construction of Guangdong, Fujian and Zhejiang coastal urban agglomerations by improving the national road network, improving the traffic capacity of the eastern coastal highway transportation channel, further strengthening the communication between the Yangtze River Delta, the west coast of the Taiwan Strait and the Pearl River Delta region, and helping Wenzhou make good use of the construction of coastal city clusters in Guangdong, Fujian and Zhejiang. important meaning. Since then, the journey time for citizens of Yueqing in Wenzhou to cross the river to Wenzhou Longwan International Airport has been shortened from more than one hour to 15 minutes.

Six Breakthroughs / Looking at the Chinese Bridge

1

The world's first three-tower four-span double-layer steel truss girder suspension bridge structure

Oujiang Beikou Bridge

my country and the world at present

The most technical difficulty, the construction process

one of the most complex bridges

Adopt three-tower four-span double-layer steel truss structure

world's first

The bridge includes south anchorage, south tower, middle tower and north tower

Main structures such as north anchorage, main cable and main beam

The average height of the 3 main towers is 139 meters

The main girder on the upper part of the bridge

It is composed of 110 steel truss beams

The bridge has two main cables

Each main cable consists of 169 strands and is 2300 meters long

Can lift about 1.5 "Liaoning" aircraft carriers

Total wire length of the two main cables

Combined, it can circle the earth 2 times

2

The world's first multi-tower continuous-span suspension bridge with high stiffness concrete mid-tower

Oujiang Beikou Bridge is in the estuary area

The marine environment is highly corrosive to steel structures

Concrete tower durability and corrosion resistance

Better than steel structure

And the post-maintenance work is greatly reduced

at the same time

In order to reduce the deformation of the main beam under the action of the moving load

Improve the driving comfort after the completion of the main bridge

The bridge was finally adopted

Longitudinal A-shaped concrete tower scheme

This is a world first

3

The world's first deep silty clay super-large caisson foundation in the estuary of strong tides

Anchor is an important part of suspension bridge

The caisson is one of the basic forms of anchorage

It is buried deep in the ground, on which sits the anchor body

The anchor body anchors the main cable of the bridge

bear the load of the entire bridge

South Anchorage of Oujiang Beikou Bridge

caisson plane size area

Equivalent to 10 standard basketball courts

22 storeys high

About 230,000 cubic meters of shared concrete

The total weight of the caisson is 500,000 tons

sinking process

like in "cream" and "gummy"

Stabilize the giant "scale weight"

Give caisson attitude control

and steady sinking brings many challenges

CCCC Second Aviation Administration Project Team

Innovative research and development of "underwater rapid soil borrowing device"

Design inspired by quadcopter drones

By installing four sets of reamers

Cutting the soil to form lumpy soil

Then suck it out through the air suction pump

Effectively solve the problem of soil borrowing from clay silt layer

4

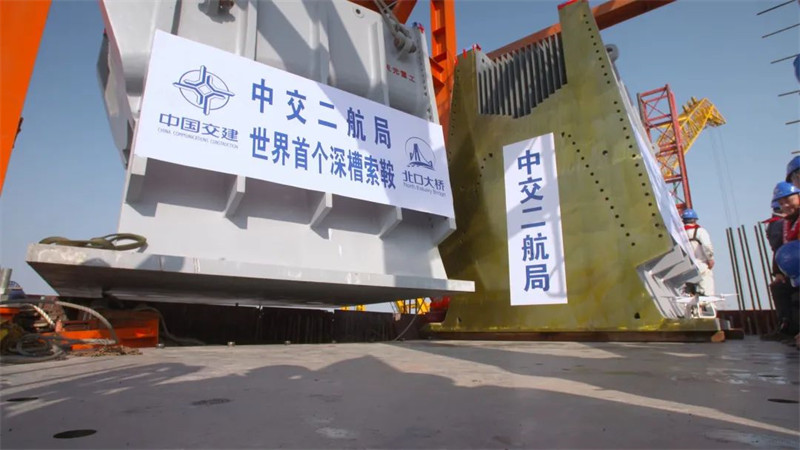

The world's first deep groove saddle

- The largest "comb" in the world

Oujiang Beikou Bridge is designed with 3 main towers

A "cable saddle" is installed on top of each main tower

The role of the saddle is to place the main cable strands

As a transition force point of the main cable corner

Evenly transfer the load to the main tower

The saddle looks like a "comb" in appearance

The gap between its baffles is used to place the main cable strands

Middle tower cable saddle of Oujiang Beikou Bridge

Its comb plate (clapboard)

20 to 30 cm from common cable saddles

increased to 90 cm

This is the world's first deep groove saddle

Can be vividly called the world's largest "comb"

5

The first intelligent deep groove saddle robot in China

Using a robot to "comb the hair" of the bridge

Stranding into the saddle is one of the key processes in the erection of the main cable

To put the main cable strands in

In deep grooved cable saddles with vertical partitions

If manual smashing is used

It is easy to cause loose wire, skip wire, drum wire, etc.

and cannot be placed accurately and quickly

Inside the vertical bulkhead of the cable saddle with a depth of close to 1 meter

CCCC Second Aviation Administration Project Team

Successfully developed the first intelligent deep groove saddle robot in China

The robot uses a hydraulic ejector as a manipulator

"Push" the cable strand into the cable saddle

Successfully solve the problem of jumping wire and random wire

Saddle ergonomics increased by 30%

6

The world's largest lifting capacity cable-mounted crane

The heavy weapons of the great powers provoke "thousands of jins"

Steel truss girder of upper structure of Oujiang Beikou Bridge

A total of 110 hoisting sections, nearly 80,000 tons

Among them, the maximum weight of a single segment exceeds 800 tons]

how to be on the water

How about splicing together such a heavy steel truss beam?

Suspension bridge installation equipment developed by CCCC Second Aviation Bureau

The world's largest lifting capacity cable-mounted crane

The 1,000-ton cable-mounted crane provokes a "burden"

Easily walk the "tightrope" at a height of 100 meters

Its novel design and simple structure

At the same time, it has the function of large inclination swing

solved

Large-tonnage, long-span suspension bridge box girder section hoisting

Poor synchronization stability, lifting capacity

and the problem that the lifting speed cannot be guaranteed

2017-2022/ Bridge Growth

▲ On May 15, 2018, the first sinking of the caisson in Nanmo Anchorage was completed.

▲ On November 20, 2018, the construction of the south tower cap was completed.

▲ On November 11, 2019, the construction of the towers of the South Tower was completed.

▲ On March 26, 2020, the South Tower was successfully capped.

▲ On April 12, 2020, the construction of the caisson in the Nanmo Anchorage was completed.

▲ On February 24, 2021, the first main cable strand was erected.

▲ On April 7, 2021, all the main cables of the bridge were erected.

▲ On July 14, 2021, the bridge entered a new stage of steel girder erection.

▲ On October 15, 2021, the bridge completed the hoisting of the steel truss girder in the intersection area of the cable girder.

▲ On December 30, 2021, the bridge was successfully closed.

▲ On January 14, 2022, the main works of the bridge will be completed.

▲ On April 22, 2022, the asphalt paving of the steel deck of the main bridge of the bridge was completed.

▲ On May 9, 2022, the main bridge completed the load test.

▲ On May 27, 2022, the bridge was completed and opened to traffic.

The original intention is not changed, and the struggle is hard

Tribute to bridge builders

Upvote for China Bridge