Recently, the pipe jacking of No. 2 entrance of Furong District Government Station of Changsha Rail Transit Line 6, built by the First Public Bureau of China Communications and topped by Guangzhou Jintu, has been successfully completed. The smooth implementation of this project fills the blank of our company's rectangular pipe jacking project in water-rich cobble-gravel stratum and provides experience reference for rectangular pipe jacking construction in similar stratum.

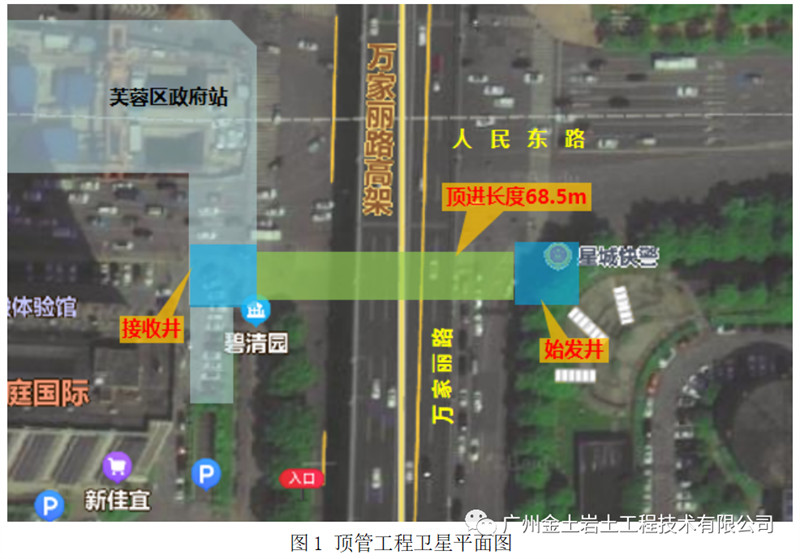

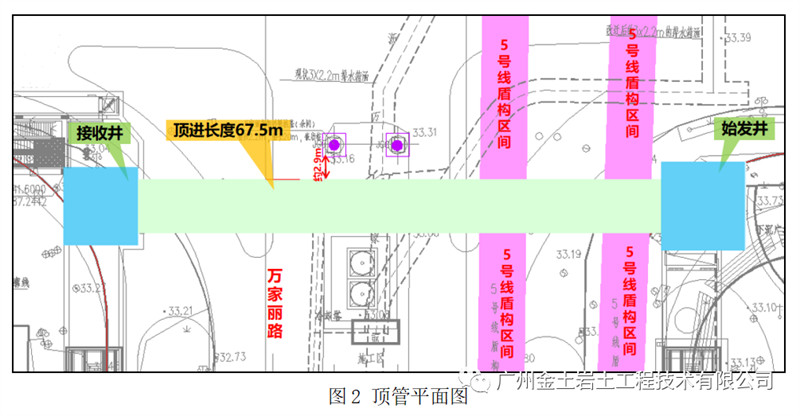

The project is located near the intersection of People's East Road and Wanli Road. The planned entrance and exit passageway will cross Wanli Road and Wanli Viaduct from west to east. Over the existing metro line 5 section. The ground traffic is busy, the traffic flow is huge, the underground municipal pipeline is numerous, and the surrounding buildings (structures) are dense, which are mainly commercial land, public management land, park green land and residential land.

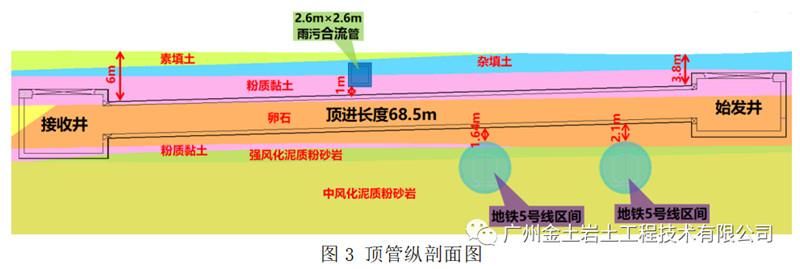

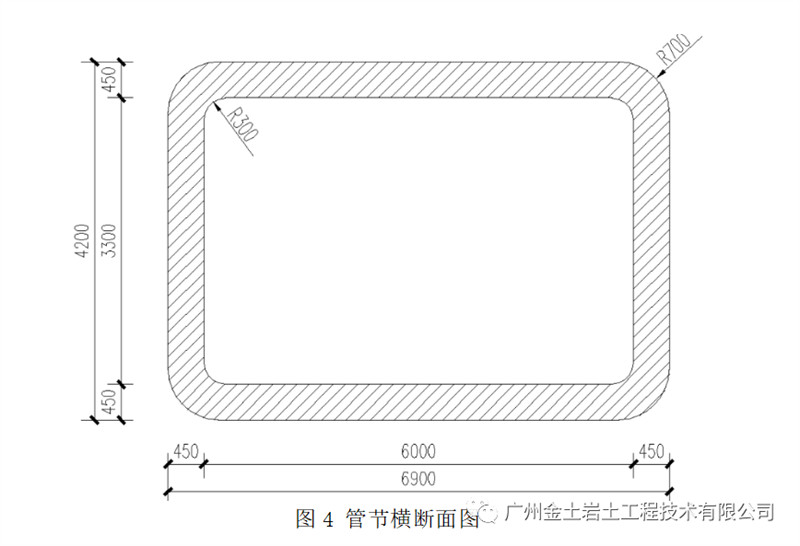

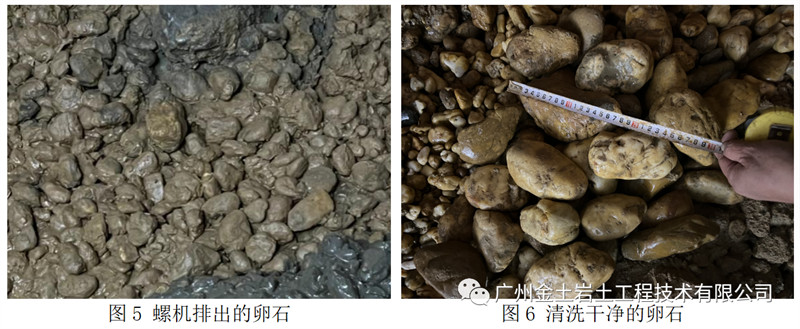

The section size of pipe jacking is 6.9m×4.2m, the length is 68.5m, the thickness of the overlying soil is about 3.8m~6.0m, and the jacking is 2.8% into the longitudinal slope. The stratum through is mainly pebble, and the local is silty clay. Among them, the largest particle size of pebbles is 18cm, with large particle size, high strength and strong permeability. The groundwater level of the site is about 2.5m~4.6m, and the groundwater is mainly confined water with a pressure head of 1m~4m.

Project features:

1. Pipe jacking under the municipal main road, 2.9m side through viaduct pile, 1.0m short distance through rain sewage pipe, high requirements for road and bridge pile settlement deformation control and pipeline protection during construction.

2. The tube jacking spans the metro section already in operation, and its minimum vertical clear distance is about 1.64m. During construction, it is easy to cause disturbance to the metro section, which is easy to lead to floating, deformation and cracking, and has high requirements for subway protection. In the jacking construction, the movable counterweight should be set in the passageway and the deformation monitoring should be strengthened.

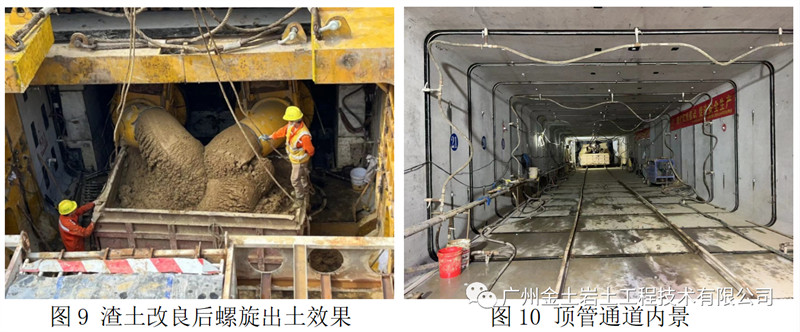

3. the pipe jacking through the middle and lower stratum is mainly pebble layer, the upper part is filled with soil, silty clay, and the construction encountered fluid sand, fine sand, the formation is soft and hard, uneven left and right, easy to make the pipe jacking machine torsion, attitude control is difficult.

4. The maximum particle size of the pebble is 18cm, which has large particle size, high strength and strong permeability, leading to the excavation difficulty and gushing of the spiral excavator.

5. The abandoned PEC tube in the jacking process is easy to make the screw machine blocked and stuck.

With rich experience in pipe jacking construction, our company carries out targeted design, strengthening and transformation of cutter head, tool and screw excavator before pipe jacking construction. During the jacking process, special improvement liquid is used to carry out targeted improvement on pebble stratum. At the same time, it is cooperated with the composite thick mud lubrication and drag reduction developed by our company. A series of problems such as large current of cutter head of pipe jacking machine, slow driving speed, difficult attitude control, difficulty in excavation of screw machine and gushing were successfully overcome by jacking machine in bad sand and gravel stratum, and the pipe jacking construction task was successfully completed.