On November 18, with the last truck of concrete pumping finished, the main bridge of Xiangxuzhou East Branch pier 21 0, 1# block box girder casting was completed, so far, all the main pier 0, 1# block box girder node tasks of Xiangxuzhou Bridge were successfully completed.

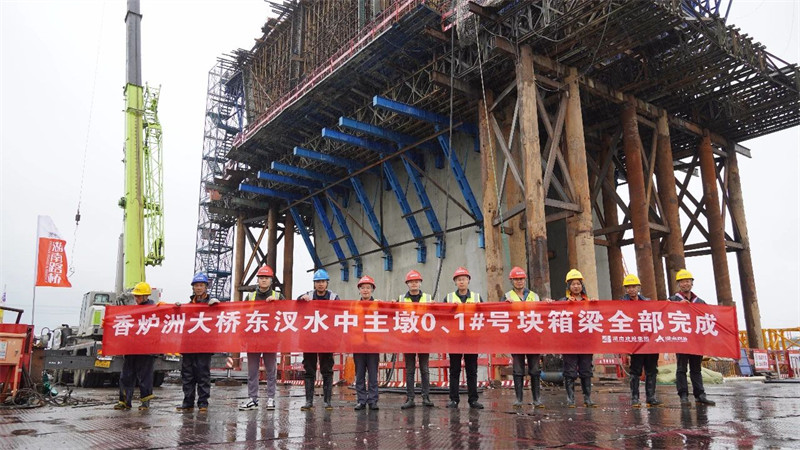

Construction site

The main bridge of Xiangxuzhou Bridge East Branch Channel adopts (88.5m+2*165m+88.5m) prestressed concrete continuous rigid system, the main pier 0, 1# block is 16m long, the top of the beam is 34.5m wide, the root of the main beam is 10m high, it is a single box with three chambers of inclined web box section, 0, 1# block adopts assembly bracket construction technology. The project team optimized the concrete ratio and reasonably planned the construction organization to ensure the quality of concrete pouring. In order to ensure that the process was completed on schedule, the project opened a "two-shift" operation mode of day and night, carried out squatting and mapping checks at each process node and difficult point, formulated a detailed construction plan for construction preparation, construction process, concrete supply, equipment and materials, and emergency disposal, and clarified the technical specifications and operation procedures of each process. To ensure the smooth completion of the box girder pouring of block 0 and 1. During the construction process, the division of labor was refined, and the project strictly controlled the quality and safety during the casting process, carried out detailed technical and safety briefing, and ensured that the safety protection measures were fully implemented to ensure the construction safety was controllable and the quality was excellent.

After the main pier 0 and 1# blocks are poured, the main bridge of Xiangxuzhou Bridge enters the hanging basket construction stage. The project team will make every effort to ensure the safe, high-quality and efficient completion of the construction of Xiangxuzhou Bridge.